تفاصيل الأخبار

Have you encountered product rework due to inadequate coating wear resistance? Or performance issues stemming from easily abraded textiles? In today’s highly competitive manufacturing environment, material wear resistance is a critical factor influencing product durability and overall quality perception.

We now introduce a next-generation abrasion testing instrument that redefines conventional testing paradigms —— BEVS 2816 AI Rotary Abraser. Enhanced by AI-driven algorithms, this system delivers higher testing accuracy, real-time data analysis, and improved repeatability—empowering R&D and QA laboratories to optimize workflows, reduce testing costs, and accelerate product development cycles.

Built for Precision, Powered by Intelligence, Designed for Efficiency

Powered by Intelligence

BEVS 2816 AI Rotary Abraser integrates AI voice control, IoT-based LIMS connectivity, and precision mechanical engineering—specifically designed to solve common pain points in traditional wear resistance testing.

✅ Intelligent Operation — Minimize Manual Effort

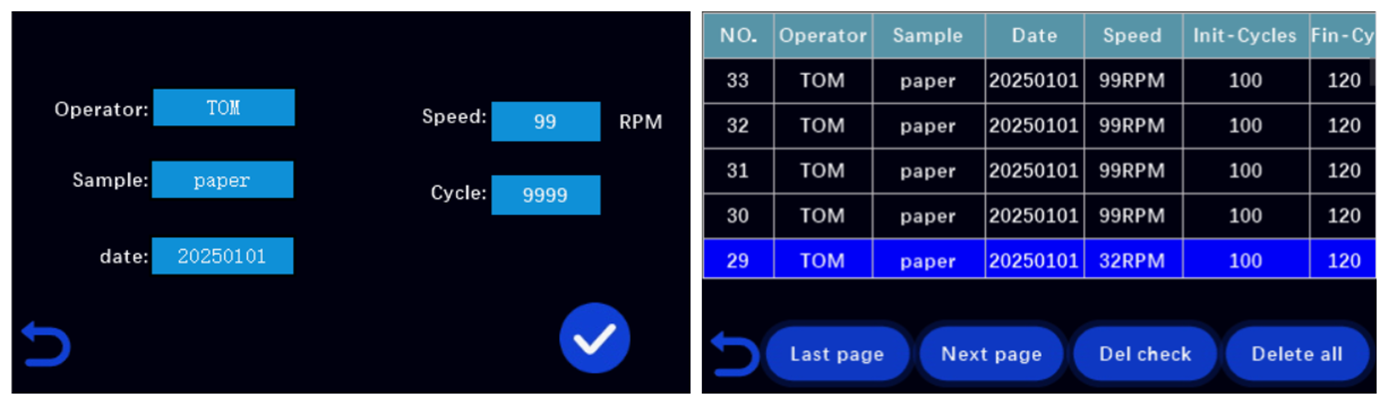

AI Voice + Touchscreen Dual Control: Fully visualized interface with voice command enables easy operation, even for non-specialists.

Auto Counting & Reset: Set the desired cycle count; the system runs automatically and displays results upon completion—reducing human error.

✅ High Precision — Reliable, Standardized Results

Dual Abrasive Wheel System: Fully compliant with GB/T 1768, ISO 7784, and other international standards. Compatible with over 10 material types including leather, coatings, plastics, and textiles.

Adjustable Load Mechanism: Includes a standard set of calibrated weights for variable testing conditions.

✅ Clear Data Management — At a Glance

IoT-Enabled LIMS Integration: Real-time monitoring of device status with support for data export and statistical analysis.

Auto Data Storage: Capable of storing up to 1,000 test records, ensuring traceability and easy retrieval.

△User-friendly interface

✅ Efficient Cleaning — Save Time and Effort

External Dust Collector Included: Comes with a dedicated vacuum unit that actively removes debris during testing, helping to prevent dust contamination of both samples and equipment.

From Lab to Market: Customer Success Stories

Cross-Industry Validation with Real-World Results

Case 1: Enhanced Abrasion Resistance for EV Tires

Client: Leading new energy vehicle manufacturer

Challenge: Rapid tread wear during road tests despite strong lab performance

Solution

Simulation of gravel and asphalt road surfaces using H-18 wheels

1,000g load, 60 rpm (5,000 cycles) & 1,000g load, 90 rpm (9,999 cycles)

Results:

35% improvement in abrasion resistance

50% increase in tire lifespan

ISO certification achieved, opening European market

Case 2: Durability Validation of Furniture Coatings

Client: Premium solid wood furniture brand

Challenge: Cracking and peeling of coating at the knee area of sofas, poor manual visual inspection efficiency

Solution

CS-10 abrasive wheels used for 1,000 cycles of testing at 750g load, 60 rpm

Simulated 10-year usage cycle

Results:

Coating abrasion rating improved by 15%

Reduced inspection costs by 70%

Lead time accelerated by 3×

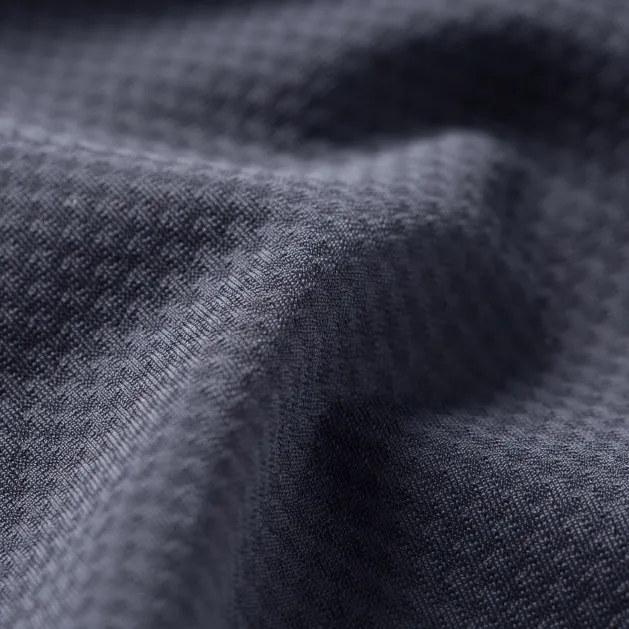

Case 3: Abrasion Performance Optimization for Sportswear Fabrics

Client: Sports apparel company

Challenge: Fabric abrasion at knees during wear, traditional tests unable to replicate dynamic friction

Solution

Custom CS-10 wheels (flexible material) simulated friction pattern during running

Testing on various fabric thicknesses for activity intensity abrasion

Results:

200% increase in abrasion resistance

Successfully integrated into global sports brand supply chain

Copyright(C)BEVS Industrial Co., Ltd.